Fiber Pave

Source: Fiberized Products, Inc.

FiberVisions, Inc., through its own research and development, as well as independent laboratories and universities, has developed a high quality polypropylene fiber.

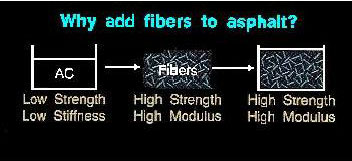

Synthetic fibers have been added to asphalt paring mixtures for years. They have been proven to increase the strength and reduce reflective cracking. FiberVisions, Inc., through its own research and development, as well as independent laboratories and universities, has developed a high quality polypropylene fiber. It has its own exacting standards for use in the highway industry. It is known as FIBER PAVE.

![]()

Manufacturers of other types of materials, used as additives, have attempted to equal polypropylene fiber. One such product is polyester fiber. Polyester, however, is not as successful a material.

Some reasons are as follows:

- Volume: Fiber additives should be placed in asphalt on an equal volume basis. The specific gravity of polyester is much greater than polypropylene (1.38 to 0.91). Polyester requires approximately 2r<3 more fiber (by weight) than polypropylene in order to obtain equal results. These materials are marketed by weight, so it becomes an important price consideration.

- High Adhesion to Asphalt: Polypropylene fiber is specially treated to provide high adhesion and rapid dispersion in asphalt. As a result, the blend obtained with polypropylene and AC20 has 50% more strength than polyester and AC20.

- Dispersion: Polypropylene fibers are quickly and easily dispersed in asphalt. Polyester fibers require twice the amount of mixing time.

- Resistance to H 0 Salt Alkaline and Acids: Palypropyiene fibers are not dye able (water absorbing) which means they are not affected by acids and salts. Polyester, however, retains less than 20% of its original strength after 1000 hours of exposure.

- Heat Resistance: Polyesterfibers do not melt at high temperatures. This is less restrictive on the asphalt plant, but high temperatures damage the asphalt. At high temperatures, light ends are driven from the asphalt causing a dramatic loss in asphalt ductility at low temperatures. Polypropylene begins to shorten at 300°F. The presence of polypropylene in hot mix is visual verification that the asphalt is not overheated and consequently not damaged.

Fiberized Products, Inc., 4170 Roberts Road, Columbus, OH 43228. Tel: 614-529-1030; Fax: 614-529-1933.

This website uses cookies to ensure you get the best experience on our website. Learn more