Lighthouse moving project wins ASCE outstanding project award

The moving of the huge, 5,000-ton Cape Hatteras Lighthouse was the engineering feat that won the American Society of Civil Engineers Outstanding Civil Engineering Award this year. The huge, 200-foot-high edifice was moved atop rollers in much the same fashion it is thought the blocks for the great pyramids of Egypt were moved.

Moving a 5,000-ton lighthouse almost a half a mile away from an encroaching ocean was the project that captured the Outstanding Civil Engineering Achievement Award presented by the American Society of Civil Engineers this year. The winner was announced at ASCE's OPAL Awards Dinner this week in Washington, D.C.

The Cape Hatteras Light Station Relocation Project, conducted by the National Park Service, Cape Hatteras National Seashore, was selected tops among 27 projects by a six-member blue-ribbon panel of prominent engineers and journalists, including Public Works Online Editor Joyce Jungclaus.

The Cape Hatteras Lighthouse, located on North Carolina's Outer Banks, was being threatened by erosion when the National Park Service sought a plan to help ensure the lighthouse remained a fixture on the Outer Banks and in the hearts and imagination of people all around the world.

It is the world's tallest brick lighthouse

The Cape Hatteras Light Station Complex was constructed 1,600 feet from the Atlantic Ocean, and includes the world's tallest brick lighthouse (200 feet above ground), two keeper's quarters, an oil house, three water cisterns, and other historic features. The height was deemed necessary because the Diamond Shoals (Graveyard of the Atlantic) require vessels to navigate at least 15 miles from the coast.

Constructed of 1.25 million bricks and over 1,500 tons of granite, the lighthouse weighs approximately 5,000 tons. It could easily withstand hurricane force winds, but was no match for the unrelenting effects of coastal erosion. Since the 1870 lighthouse completion, the shoreline had eroded to within 120 feet of the structure and continues to erode at a rate of 10 feet per year. The challenge of this project was to successfully relocate the entire light station complex to a site 2,900 feet to the southwest, placing it once again 1,600 feet from the shoreline.

From this vantagepoint one can see the ocean creeping closer to the historic lighthouse. It is easy to imagine how the old lighthouse could succumb to the ocean within the next decade as predicted.

Most experts agreed that if not moved, the lighthouse would eventually (within 10 years) succumb to the ocean, but there was some opposition to moving for various reasons. Many people did not believe the lighthouse could be moved without suffering irreparable damage. If the lighthouse were destroyed during a move, not only would a national treasure be lost forever, but way a life built on tourism would be negatively impacted.

Relocation wins as best solution

After more than 10 years of evaluation and funding battles, the NPS determined that relocation was the most cost-effective and environmentally-responsible method to preserve the Light Station. Recognizing the unique blend of engineering and construction skills needed, the NPS selected a design-build approach. The design/build team, which encompassed 22 technical disciplines including 10 engineering disciplines, was selected in 1998 and consisted of seven firms lead by the prime general contractor, International Chimney Corporation. Management of the seven-member design team was complex. However, e-mail, consistent CADD drawing and specification standards and formats, and regularly scheduled meetings and reviews ensured the effective communication necessary to accomplish the project work scope.

As a design/build project, team member firms were connected throughout design and construction. The team established an internal, self-policing Quality Assurance/Quality Control Program geared toward the design and construction phases.

All structures need to be relocated before hurricane season hit the Outer Banks

The overall construction schedule required relocation of all structures completed before hurricane season for the Outer Banks (August to October). The team placed emphasis on completing the relocation by mid-June to July and developed emergency plans for weather conditions that could put the project at risk such as site flooding, localized erosion, and high winds.

The move required careful sequencing of activities. The work began with excavation and dewatering to reach the original timber mat foundation. Because the timbers had been permanently submerged in fresh water, the dewatering had to be carefully controlled to prevent them from drying. The six feet of the granite base below ground (800 tons) then had to be removed. As the granite was removed and partially salvaged, it was replaced with a steel beam mat resting on the old timbers and a system of 136 steel shoring towers and cross bracing assemblies.

Fourteen 72-foot main steel beams and 15 60-foot cross steel beams were installed in a crossing pattern among the shoring towers beneath the lighthouse and surrounded by a perimeter of four large, steel strong back beams. This steel framework served as the temporary foundation. The main beams were placed in twin configurations at seven locations to house the 100, hydraulic 100-ton capacity jacks on 4-foot centers between the twin beams.

Here the enormous, 5-ton structure is lifted above the ground for placement on rollers to move toward its new location.

Before moving, the lighthouse had to be lifted up 6 feet vertically so the track steel beams could be slid underneath. Oak timbers (cribbing) were stacked to support the load of the jacks during the vertical lift. A system of steel mat steps on compacted stone was devised to allow smooth transition for moving off the existing foundation and later onto the new foundation.

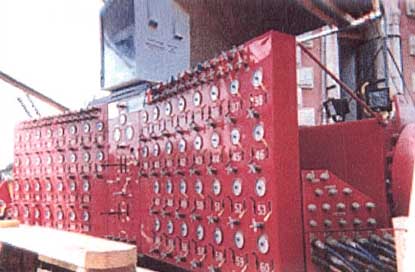

A broad array of controls governs the jack lifting the lighthouse.

For moving, the jacks pressed downward onto Hilman Rollers which rolled along seven track beams laid on the prepared move path. Adaptation of specialized hydraulic jacking systems to control the lighthouse tilt was an essential factor in the successful move. By dividing the jacks into three separately controlled zones, the lighthouse structural support frame could be maintained in a level plane, and the structure could accommodate local move route settlement and deflections in the steel mats and track steel.

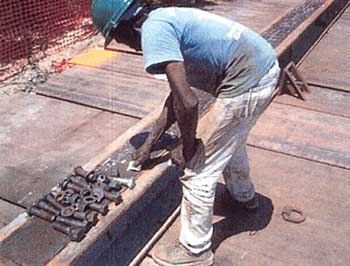

Keeping the track well lubricated was important throughout the process.

Five, 50-ton push jacks were mounted to react against the track steel and push on five of the seven main twin beams to slowly move the lighthouse forward in 4 to 5 foot increments at 1 to 2 inches per minute. A special hydraulic clamp was used for the first time to lock and release the push jacks, allowing rapid resetting of the push jacks between each push. This technique was the main factor in accelerating the move schedule.

Geotechnical engineers evaluated route

Evaluating move route soils and predicting settlements during move challenged geotechnical engineers. In-situ testing and large-scale load tests allowed accurate settlement predictions so movers could anticipate and adjust for settlement. The lighthouse was extensively instrumented using conventional and electronic means. The tilt, in particular, was monitored through a realtime computer display available to the jack control operator.

The move corridor was graded level, and loose, exposed sands were compacted and topped with 12 inches of compacted crushed stone. The stone surface was overlain by steel mat sections (five 10-inch beams welded together to form a single mat section) placed edge to edge. The track steel was laid on the steel mats. In order to minimize the amount of materials required on site, mat steel, track steel, and crushed stone were "leapfrogged" from behind and placed forward of the moving lighthouse.

Erosion controls were implemented

Steps were taken to ensure that move corridor preparations had minimal impact on the physical environment. Clearing was restricted to the minimum needed (100 feet wide) and proper erosion and sedimentation controls were implemented. After consultation with NPS naturalists, lighting planned along the move corridor was eliminated and temporary, directed light stations were used when needed to minimize potential for disrupting nesting activities of endangered sea turtles.

The Cape Hatteras Lighthouse began its journey on Thursday, June 17, 1999, and arrived at the new location on Friday, July 9, about three weeks ahead of schedule.

The new foundation is a 4-foot thick, 60-foot square reinforced concrete mat, and founded about 9 feet below the ground. Design of the new reinforced concrete mat to accommodate a heavy load moving on from the side required careful structural evaluation and design of reinforcing due to the changing stress patterns. Once the lighthouse was over the new mat, the steel members were removed and the steel shoring posts were reinserted to provide temporary support. Special structural brick was then used to fill the space between the mat and the lighthouse base. The shoring posts were gradually removed as the total weight of the lighthouse was shifted to the brick in-fill foundation.

Project on time and within budget

The project was completed on time and within the $9.8 million budget. The lighthouse and the other structures were not damaged by the move. As required by NPS, all structures were placed in the same spatial arrangement as they had been at the original location.

In preparation for the move, the lighthouse beacon was turned off on March 1, 1999. Hurricanes Dennis and Floyd twice forced a relighting ceremony planned for September to be canceled and brought home to all that the move was the "right thing to do." On Nov. 13, 1999, exactly eight months and 11 days after it was extinguished, the lighthouse beacon blazed again, providing a historic guiding light for a new millennium. The success of the Cape Hatteras Light Station Relocation preserved the historic context of the original structures for future generations and increases interest in "moving" as a means of preservation for other endangered structures.

Edited by Joyce Everhart Jungclaus, Editor, Public Works Online

Information provided by ASCE